物づくりは人づくり - EXPERIENCE THE JOY OF REINVENTING ORGANIZATIONS!

Value Stream Mapping - 3 x 2-day Workshop & Training Program

Value Stream Mapping - Learning to See Business Holistically

Why Value Stream Mapping?

Today's Manufacturing has become much more complex than its was about a decade and a half ago. As customer demands both of features and quality are put on the manufacturers, it is becoming increasingly difficult to manage resources and processes.

Product life cycles are becoming shorter and the variants in each product is also increasing exponentially. This, therefore, puts immense pressure to reduce and maintain manufacturing costs.

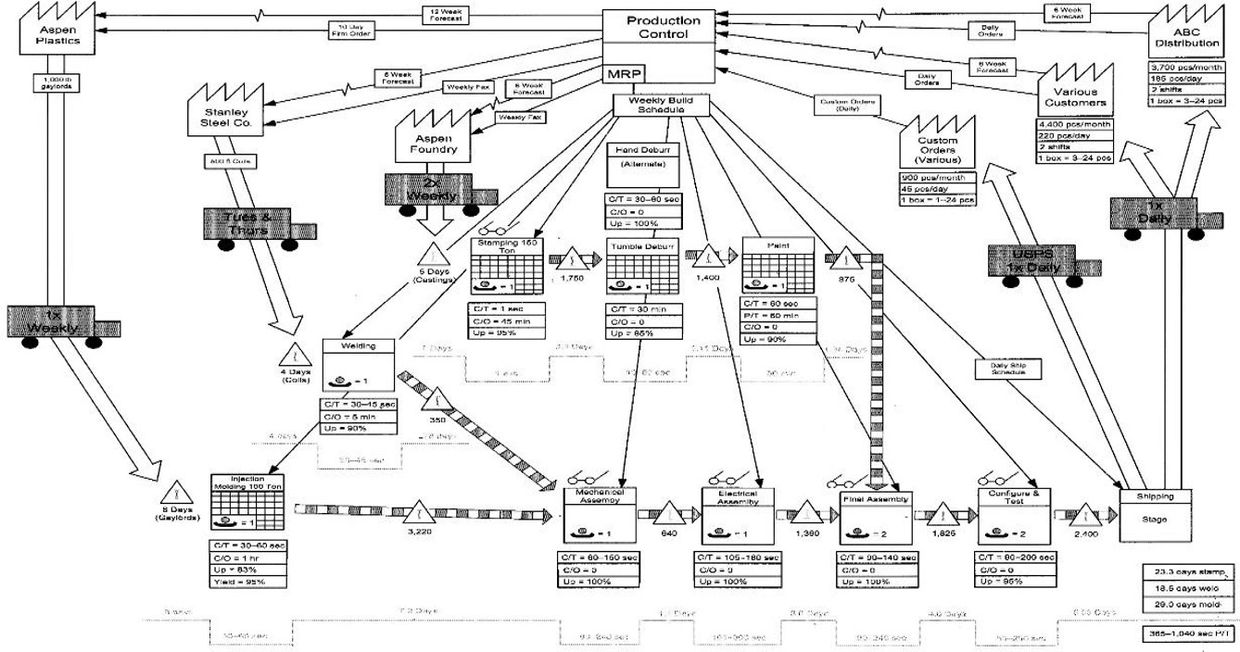

Value Stream Mapping is both a concept and technique to counter the complexities of today's complex manufacturing requirements while maintaining the quality, cost and delivery to the customer with optimized inventory and reasonable profitability.

The Value Stream Mapping Program at The School for Gemba Excellence is a step-by-step process to convert traditional manufacturing techniques into waste-free and optimized method of manufacturing.

Want to Implement Value Stream Maps? 6-month Program

If you are interested to implement Value Stream Mapping concepts in your company you can approach us directly. This is a 6-month program.

Value Stream Mapping Program

Challenges of the Real Factory -

- HIGH PRODUCT MIX -

- Flow can be hard to see when Products have multitude of options; Variations in Lead times and cycle times; Intertwining between multiple processes

- High variety of products/ services may make it difficult to define product families

- High mix of products that share the same line or equipment also makes it harder to schedule due to availability of machines and capacity

- Higher inventories on the floor, which in turn leads to longer lead times, missing parts, increased costs

- Visibility on shop floor is impossible

- Identifying and managing bottlenecks becomes a full-time job

- Managers can’t tell how the plant is performing

- SHARED RESOURCES

- Almost all factories have shared equipment - E.g., stamping m/c, ovens, injection molding, presses etc.

- Capital intensive and monitored tightly from an accounting standpoint

- Measurements like machine utilization, variance and productivity lead to large batch sizes to optimize machine utilization

- Scheduling attempts to reduce setups combining runs

- Lot sizes determined by EOQ [Economic Order Quantity]

- Parts are produced whether they are needed by the next process or not

- Changeovers are made on the basis ofwhich salesman screams the loudest

- Focus is on process optimization rather than flow optimization

- INFORMATION FLOWS

- Very difficult to see in a manufacturing environment

- May seem to change by the minute

- Operators and supervisors constantly review inventories and priorities and adjust schedules dynamically

- Production control seeks accurate, by-the-minute counts to key into MRP systems in order to plan around equipment failures and part shortages

Program Details & Who Can Attend?

The program teaches you to look at connected flow between processes. The Value Stream thinking concept helps you to synchronize customer demand with your manufacturing rate through the concept of Takt time. It helps to create the Current State Value Stream Map based on the current working and analyze it by the following steps:

- Produce to your Takt Time

- Develop Continuous Flow wherever possible

- Use supermarkets to control production where continuous flow does not extend upstream

- Try to send the customer schedule to only one production process

- Distribute the production of different products evenly over time at the pacemaker process

- Create an initial pull by releasing & withdrawing small, consistent increments of work at the pacemaker process.

- Develop the ability to make every-part-every-day in fabrication processes upstream of the pacemaker process

By analyzing the Current State Value Stream and visualizing what you want to see your company in the timed-future, you create the future state map and are able to visualize the obstacles that are restraining your company to reach that future state.

The gaps become the Kaizens that you need to execute to reach the future state that you desire.

The program is very useful for PLANT & OPERATIONAL MANAGERS, TOP MANAGEMENT PROFESSIONALS who want to set FUTURE GROWTH STRATEGIES for their businesses.

Program Structure

The Value Stream Mapping Program is divided into 4 parts:

- BASIC LEVEL: This level introduces you to the purpose of Value Stream Mapping. It facilitates the concept of identifying and eliminating waste and the various methods to apply on the shopfloor. The philosophy of flow and pull are concepts which are different forms of thinking to move away from the traditional batch or mass production concept. Finally it introduces the concept of a value stream.

- INTERMEDIATE LEVEL: This level facilitates you to create the Current State Value Stream Map step-by-step. Next it helps you analyze the current state value stream map, visualize and define your future state. By drawing the Future State Value Stream Map you will be able to define a realistic strategy for your company based on your current resources and capabilities. It will also help you to determine improvements that may be required in methods & processes, equipment & tooling, and materials to increase the current resource capability and utilization. It will also help you determine the current capabilities of your people and how much they need to improve to achieve the desired capability.

- ADVANCED LEVEL: The advance level introduces you step-by-step to the detailed concepts for the understanding and implementation of Kanban and Heijunka. It facilitates calculations for super markets and inventory levels. It also introduces and facilitates the concepts of Cycle Stock, Safety Stock and Buffer Stock. It will also introduce and facilitate the concept of the "MIZUSUMASHI" or the "Water Beetle" concept of scheduling the material handler to the various processes at the appropriate timings.

- ENTERPRISE LEVEL: This level introduces the concept of Mixed Model Value Stream. This level addresses the real challenges of the factory like High Product Mix, Shared Resources, and Information Flows for complex and multi product-high-variant value streams for multiple customers using shared resources.

Hand Holding & Projects - 6 Months Program

- Along with the training, we will coach you to implement the value stream methodology and reap the benefits from your system in terms of productivity, quality and delivery.

- We will also focus on your manufacturing costs to optimize the same by optimizing processes and inventories.

- The program is of 6 months duration with weekly visits from The School for Gemba Excellence.

- In case you are interested please feel free to contact us.

The School for Gemba Excellence

102, C Block Road, C Block, Sushant Lok II, Sector 56, Gurugram, Haryana, India

Copyright © 2021 The School for Gemba Excellence INDIA - SFGE INDIA - TRANSFORMING LIVES - All Rights Reserved.

Powered by GoDaddy

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.