物づくりは人づくり - EXPERIENCE THE JOY OF REINVENTING ORGANIZATIONS!

phenomenon-mechanism analysis <P-M Analysis>

About P-M Analysis

TPM can be defined as a set of activities for restoring an equioment to its optimal conditions and changing the work environment to maintain these conditions.

This nutshell definition highlights the principla shopfloor activities pursued in a TPM program: focused improvement or process improvement to reduce losses and collaborative maintainence carried out by production workers and skilled maintenance technicians

Both types of activity are critical to the success of a TPM program. But although preventive and autonomous maintenance are practiced in many Indian manufacturing environments today, programs for systematic equipment improvement that go beyond the cope of the restoration and repair are usually found only in moe advanced TPM implementations.

About the P-M Workshop

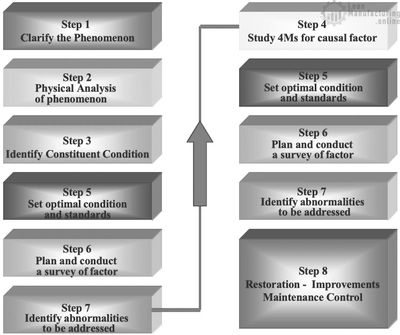

This workshop will help correct this imbalance. This workshop details a comprehensive 8-step method that has successfully eliminated chronic equipment-related problems in many companies.

Chronic loss includes the final 1 to 5% of problems that must be solved to achieve a ZERO-DEFECT/ZERO-FAILURE environment. Chronic qulity defects, are especially difficult to eradicate, because they often have multiple, interrelated causes that vary with every occurrence.

Common improvement strategies like Pareto Analysis and Cause-and-Effect Analysis are typically ineffecitve in dealing with such complex problems.

P-M analysis was developed especially to overcome the weaknesses of the traditional methods. Brainstorming and factor analysis are replaced by a rigorous analytical approach that identifies all potential causal factors. And, the accepted principle of prioritization is is suspended at key points to ensure that all factors are addressed.

Individual P-M analysis projects are conducted on a priority basis, but for each defect phenomenon or failure studied, all possible causal factors are identified, and every factor exhibiting abnormal conditions is investigated and corrected - regardless of the suspected degree of contribution.

Who Can Attend?

This workshop is suitable for all Production, Quality, Product & Process Engineering, NPD, and Maintenance Managers and Supervisors. This is the ultimate technique to approach real ZERO DEFECT.

Workshop Contents - Day-1

- Chronic Loss

- What is P-M Analysis?

- Fundamentals of Physical Analysis

Workshop Contents - Day-2

- Implementing P-M Analysis

- P-M Analysis Practice & Case Studies

The School for Gemba Excellence

102, C Block Road, C Block, Sushant Lok II, Sector 56, Gurugram, Haryana, India

Copyright © 2021 The School for Gemba Excellence INDIA - SFGE INDIA - TRANSFORMING LIVES - All Rights Reserved.

Powered by GoDaddy

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.